Effective Solutions for Aggressive Environments!

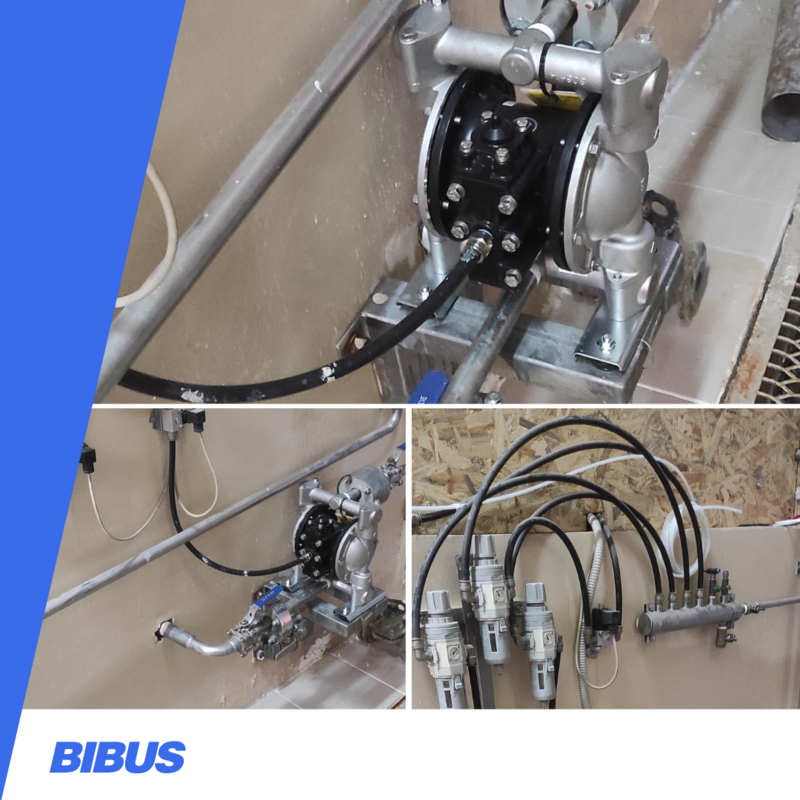

We recently completed a successful project for the safe transportation of a chemically active product for our client specializing in yeast production.

Challenge:

Ensure the transfer of an aggressive substance from the storage tank to the production line.

Key requirements:

- Prevent product leakage

- Eliminate flow pulsations

- Ensure maximum process safety

Our Solution:

- We provided a stainless steel diaphragm pump with a PTFE-coated pneumatic distributor, offering corrosion resistance and extended equipment lifespan.

- Additionally, we installed a pulsation dampener, ensuring a steady fluid flow and enabling the use of flow meters for precise monitoring.

Customer Benefits:

- Safe and efficient transportation of aggressive substances

- Increased production capacity

- Cost optimization thanks to durability and maintainability

This solution is ideal for the food, pharmaceutical, and chemical industries.

Looking for a reliable solution for similar challenges? Contact us — we're always ready to help!

Off-line Filtration - Trends in Technology

Are there specific types of off-line filtration which are increasingly used? If so, why?

Yes, we see that the demand for mobile units with integrated…

New high response servovalves DUPLOMATIC

Efficiency, speed, accuracy, repeatability and programmable control are only few of the many benefits of proportional control applied on…