Effective Solutions for Aggressive Environments!

We recently completed a successful project for the safe transportation of a chemically active product for our client specializing in yeast production.

Challenge:

Ensure the transfer of an aggressive substance from the storage tank to the production line.

Key requirements:

- Prevent product leakage

- Eliminate flow pulsations

- Ensure maximum process safety

Our Solution:

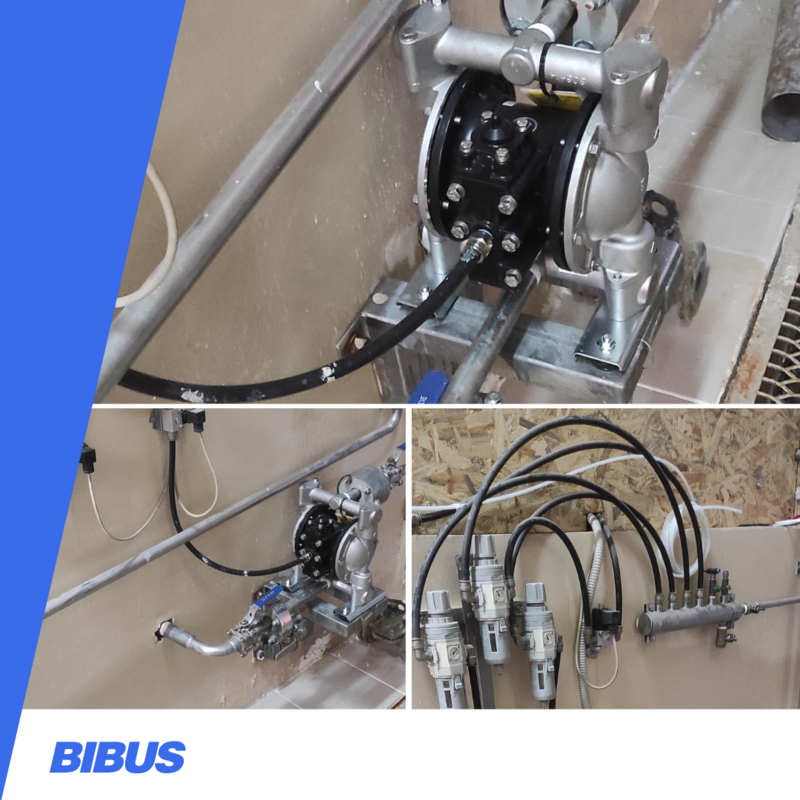

- We provided a stainless steel diaphragm pump with a PTFE-coated pneumatic distributor, offering corrosion resistance and extended equipment lifespan.

- Additionally, we installed a pulsation dampener, ensuring a steady fluid flow and enabling the use of flow meters for precise monitoring.

Customer Benefits:

- Safe and efficient transportation of aggressive substances

- Increased production capacity

- Cost optimization thanks to durability and maintainability

This solution is ideal for the food, pharmaceutical, and chemical industries.

Looking for a reliable solution for similar challenges? Contact us — we're always ready to help!

Lightweight desing for safety couplings

The coupling manufacturer R+W Antriebselemente GmbH in Klingenberg, Ger-many presents a world premier in the field of safety couplings. This…

BIBUS Ukraine took part in the International exhibition of remunerative highly effective agriculture InterAGRO-2015

BIBUS Ukraine took part in the International exhibition of remunerative highly effective agriculture InterAGRO-2015 (27.10.2015-29.10.2015, Kiev,…