Vacuum Systems D.V.P. Vacuum Technology

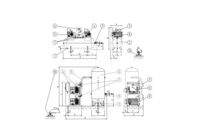

The pump-receiver group series CPV have been designed for a wide range of application needs, and are available in various versions. These units have been designed and built for use on glass and marble machinery, and on machines in which it is possible to intake non-aggressive liquids (normally refrigerant liquids). These are complete, compact units and are normally connected to the user machine by a flexible hose. A ball valve at the tank inlet allows it to be cut off from the system for maintenance operations. Air and liquid are first separated inside the tank by means of an internal "cyclone" device, while a level indicator with float is located outside to allow the operator to visually check the amount of liquid contained; the indicator has a sensor to emit an electrical signal when the tank is full, and an automatic valve to drain the accumulated liquid. The air in the tank, with no droplets but still damp, passes through the condensation separator filter, on which a vacuum gauge is mounted to check the operation of a unit and a ball valve for the air return (necessary to drain the water collected in the tank). The filter is connected to the pump through a pipe with a built-in auxiliary check valve. The pumps used in these groups belong to the WR series, which has a built-in high-efficiency "gas ballast" device, which allows you to separate the remaining condensation from the oil and expel it with the pump stopped.

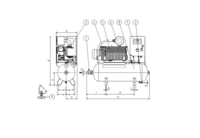

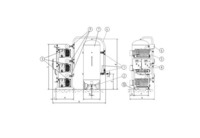

The centralized vacuum equipment models CPA are available in three different configurations SIMPLEX - DUPLEX - TRIPLEX depending on the number of pumps installed. These products are equipped with a control panel checking the pressure inside the receiver and guiding the pump starting. Developed according to European standards, panels also include the hour counter and the pump wear balancing device.

Mr. Anton Zakotenko

Mob: +38-098-697-34-85

zak@bibus.ua